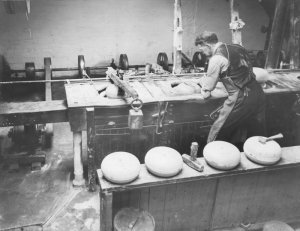

Mauchline Curling Stone Works

Manufacturers of the Olympic 2002 Stones

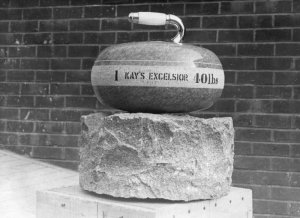

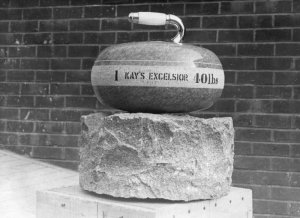

Photo Anon

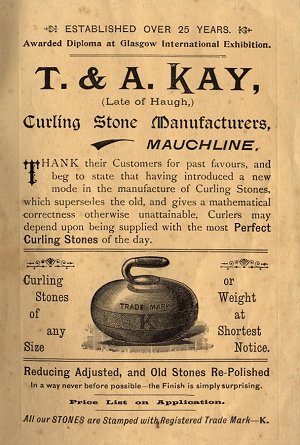

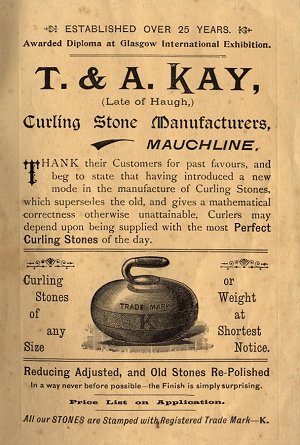

Left: An advert from a booklet from around 1906.The curling stones are made from rock quarried on Ailsa Craig.

| AYRSHIREHISTORY.COM PRESERVING THE PAST . . . . FOR THE FUTURE |

KAY'S OF |

|

|

|

|

|

|

|

|

|